5 Gallon Plastic Water Tank Blow Molding Machine

-

Min Order

1

-

Product Unit

Pieces

-

Origin

China Mainland

-

Payment

- Contact Now Start Order

- Favorites Share

- Description

Product Detail

First, the electronic control system: Japan's Mitsubishi PLC computer and human-machine interface (English or Chinese) control, color touch-screen operation. All the process set to change, retrieval, monitoring, troubleshooting and other functions are implemented on the touch screen, no point of contact with the working principle, components and durable.

Second, the hydraulic system: proportional pressure control, with imported brands Yuken hydraulic components, stable and reliable.

Third, the plasticizing system: efficient plastics mixing screw, to ensure plasticizing full uniform.

Fourth, the speed control system: VVVF + alloy steel and hard gear reducer, speed stable, low noise, durable.

Fifth, the opening and closing mold, mold transfer system: beam arm, three position, center locking clamping mechanism, to ensure long-term use. Clamping force balance, no deformation, the use of body translation mode (ball linear guide), high precision, low resistance, fast.

Sixth, blowing the needle holder: blow the whole Square-type needle holder, a solid does not shift to ensure a smooth incision products.

| Model | HTII-5L | |

| Station | Double station | |

| Max. Product Volume | (L) | 5L |

| Dry cycle | (pc/h) | 700 * 2 |

| Screw Diameter | (mm) | 70 |

| Screw L/D ratio | (L/D) | 25 |

| Screw drive power | (KW) | 22 |

| Screw heating capacity | (KW) | 6.2~8.2 |

| No. of heating zone | (ZONE) | 3 |

| Max.Output of HDPE | (Kg/hr) | 70 |

| Oil pump drive power | (KW) | 7.5 |

| Clamping force | (KN) | 60 |

| Mold stroke | (mm) | 148~508 |

| Max. Size of Mold(W*H) | (mm) | 370*390 |

| Max.Die diameter | (mm) | 145 |

| Die heat capacity | (KW) | 2.5 |

| No. of heating zone | (ZONE) | 3 |

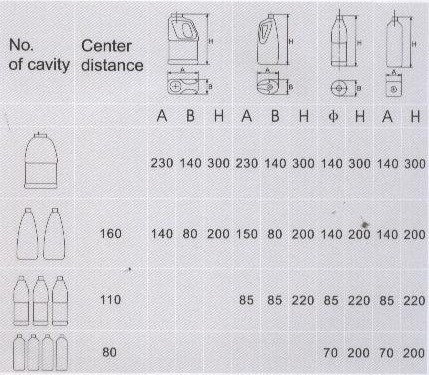

| Central distance of Double head | (mm) | 160/180 |

| Blowing pressure | (Mpa) | 0.6 |

| Air volume | (M3/MIN) | 0.4 |

| Cooling water pressure | (Mpa) | 0.2~0.3 |

| Water consumption | (L/MIN) | 60 |

| Size of machine ( L*W*H) | (m) | 3.43*2.3*2.65 |

| Weight of machine | (TON) | 5.5 |

- Single Station Extrusion Blowing Machine 1 Pieces / (Min. Order)

- Double Station Extrusion Blowing Machine 1 Pieces / (Min. Order)

- 30L Extrusion Blow Molding Machine 1 Pieces / (Min. Order)

- Drum Extrusion Blow Molding Machine 1 Pieces / (Min. Order)

- SJ Rotary Die Head Film Blowing Machine 1 Pieces / (Min. Order)

- Polythene Blow-molding Machine 1 Pieces / (Min. Order)

- SJ Rotary Die Head Film Blowing Machine 1 Pieces / (Min. Order)

- Quantitative Pillow Filling Machine 1 Pieces / (Min. Order)

- Ziplock Bag Film Blowing Machine 1 Pieces / (Min. Order)

- SJ-50 Shrink Film Blowing Machine 1 Pieces / (Min. Order)

- PE Film Blowing Machine 1 Pieces / (Min. Order)

- Plastic Film Blowing Machine 1 Pieces / (Min. Order)

- SJ65x2-CPP Coextrusion Film Blowing Machine 1 Pieces / (Min. Order)

- Vertical Balancing Machines 1 Pieces / (Min. Order)

- Propshaft Balancing Machines 1 Pieces / (Min. Order)

- HQ-16 Dynamic Balancing Machine 1 Pieces / (Min. Order)

- Vertical Gastric Wing Blowing Machine 1 Pieces / (Min. Order)

- GKC-4/40-air Blowing Machine 1 Pieces / (Min. Order)

- E-Propshaft Balancing Machines 1 Pieces / (Min. Order)

- F-Propshaft Balancing Machines 1 Pieces / (Min. Order)

Menu

Menu

Favorites

Favorites

Frequent updates ensuring high quality data

Frequent updates ensuring high quality data

Over 5000 customers trust us to help grow their business!

Over 5000 customers trust us to help grow their business!

Menu

Menu